Top Research outputs by NSHM students on ‘Unsung Manufacturing Units in Kolkata’

The Indian economy was already going through a rough patch before the arrival of the pandemic, and just about a month before the pandemic actually stepped in and shrunk our worlds to the size of our homes, we initiated a project, to find out the kind of problems faced by the small scale manufacturing units around us.

Small scale industries as we know, are important because they help in increasing employment and economic development of any nation. They are the force that improves the growth of the country in both urban and rural perspective. Small and medium-sized businesses are evolving into enablers of infrastructure and manufacturing growth, and also addressing issues like congestion, slums, violence, and various other factors. Industry in our economy depends majorly the manufacture of goods. Thus, the nose-diving of this sector has been a major concern across all tables.

We understand well the value of the manufacturing sector in reviving the economy’s fortunes. The government has also repeatedly emphasised speeding up the manufacturing sector’s development towards sustainable economic development.’Make in India’, launched in 2014 was also a step taken by the government to bolster domestic manufacturing of goods and to achieve a 25% GDP share and offer 100 million jobs in the sector by 2022. These proposals, however, have come to a grinding halt as an unexpected result of the global pandemic, and India’s manufacturing sector today seems to be at a crossroads.

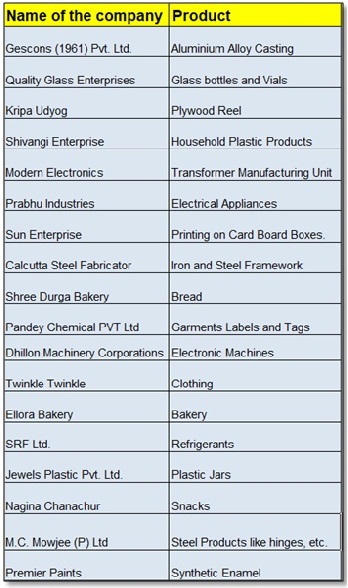

Equipped with our academic knowledge and determination of my team comprising Aman Jha, Anwesha Kundu, Sudhanshu Pandey, Mohit Kumar Bajoria, and Aryan Kumar Sinha, we started on this project on the 27th of January, 2020. As the COVID-19 was already around the corner we decided to stay close to our campus, and focus on 18 Units, and find out what are some common issues they face in stepping up their businesses. These prodcution units ranged from metallic productions, to large scale bakeries, forms of plastics, box covers, glass vials, and even cloth embroidery to small scale machinery parts. Some of them like M.C. Mowjee (P) Ltd were more than a centuries old, and Quality Glass Enterprises has been exporting their vials to several countries over a couple of decades.

We made appointments and visited the units over time, and had detailed conversations regarding the sector, number of employees, production types, their raw materials (types and sources), their problems in procurement, logistics & distribution patterns and types, about their on-going operations, other operational issues, their network plans, and also about their storage of finished goods (warehouse and locations).

It took us more than a couple of weeks, to visit all places, and get relevant information noted. While the employers were kind enough to provide us with information, we also had an amazing experience of visiting their facilities and watching how the stuff we use, are actually made.

Once we were done with our visits, the team sat down to inference results and the points that stood out commonly were the, general lack of skilled manpower in almost all units. It was observed that a small scale unit located in a remote backward area may not have problem with respect to unskilled workers, but skilled workers are not available there. Firstly, skilled workers may be unwilling to work in these places, and secondly, the organisation may not afford to pay the salary and other services these employees require. In addition to non-availability, entrepreneurs face various other issues such as absenteeism, indiscipline with high labour turnover, strike, etc. These labour-related issues lead to lower efficiency, a decrease in efficiency, an uptick in pollution and additional operating costs and eventually, a negative influence on the viability of these small-scale units.The second issue was immense troubles they face in logistics chain and have been struggling forever to build the most efficient one, inadequate and inappropriate transportation and communication network will make it all the harder for multiple units to operate.The amount, quality and production plan of the industries working in these areas would be adversely affected by all these factors, as a result of which activities would therefore become inexpensive and unviable. Finally the most striking observation was regarding their inertia to get on the online space, in order to promote or sell their businesses online which is ultimately keeping them separated and in some senses further behind the rest of the world.

We also came up with certain solutions which we think can help in overcoming the issues in hand.

- To start with, a successful marketing must cross the divide that exists between customers and small businesses.

- The government or the private bodies must arrange a number of industrial fairs, exhibits, to promote the sales of small scale industrial goods.

- The educational institutions should set independent campaigns and provide trainings to entrepreneurs from grassroots in financial, marketing, technological, managerial areas.

- We also think cells must be set up in educational institutions, which will help students get in touch and work with small and medium scale sectors around their campuses, which might result in a growth experience for everyone involved.

The three weeks, into this project resulted as a great learning experience for the entire team, and it helped us get a deeper understanding of not just the industry we might be getting into, but also of the subjects in our curriculum.

We believe educational institutions must have more of such initiatives, which will greatly help in bridging the gap between students inside the campus and industry outside of it.